Industry

Benefits of 3D laser scanning and CAD modelling in industry

- fast and efficient targeting of the actual state of objects and equipment using a 3D scanner

- non-contact measurement over long distances and in full operation

- instant visual and geometric analysis of scanned objects

- high-precision CAD modelling from measured data

- creation of drawing documentation (2D layout, 3D model, isometrics)

- analysis, optimization and visualization of solutions

- the resulting data is delivered in various CAD formats according to customer requirements (dwg, dxf, skp, jt, step, sdnf …)

- creation of 2D and 3D pdf documentation for easier access to information

- Creation of documentation of production halls in the automotive environment in Speedikon, Bentley Microstation with Tricad MS superstructure in compliance with the prescribed standards and the use of the necessary environments.

- Documentation of machinery and equipment

- Documentation of conveyors

- Documentation of technological pallets

- Documentation of steel structures, staircases and platforms (dwg, dxf, rvt, skp, step, jt…)

- Documentation of utilities (pipes, ventilation, heating, electrical distribution)

Engineering and manufacturing industry

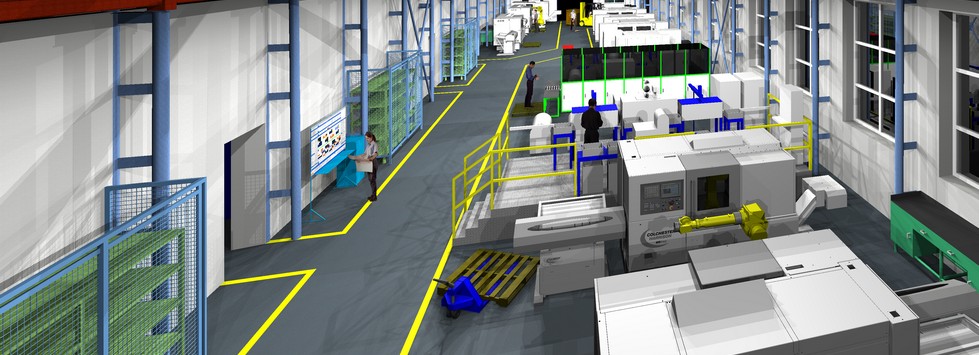

Creation of documentation of production halls

Documentation of machinery and equipment

Documentation of steel structures

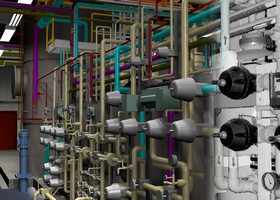

Documentation of utility networks

pipes, ventilation, heating, electrical distribution

Optimisation of the production layout

Optimisation of material flows

Sample examples for download

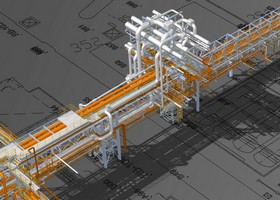

Case studies - pipeline orientation in 3D

Precise alignment of the pipeline bridge using a 3D laser scanner for projection purposes.

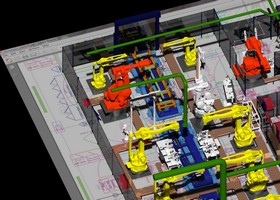

Case study - machine layout

The aim of the project was to orientate the production areas and design suitable machinery.

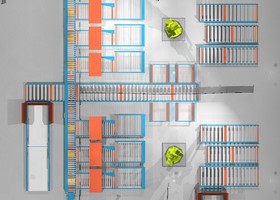

2D production hall layout

An example of creating 2D documentation from a point cloud.

Case study - automotive industry

The supplied technical documentation was used for the planning and installation of new machinery and equipment.

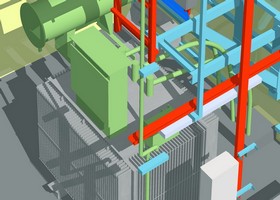

Energy industry

Precise alignment of the transformer with the Faro Focus laser scanner for maintenance purposes.

3D model of the pipeline

The aim of the project was to accurately measure the pipelines as a basis for the design of the new routes.

- Creation of documentation for maintenance and reconstruction

- Documentation of pipelines and equipment

- Documentation of steel structures also in SDNF format

- Creation of isometric drawings of pipelines