Optimisation and planning

iQservices, s.r.o.

Laser scanning

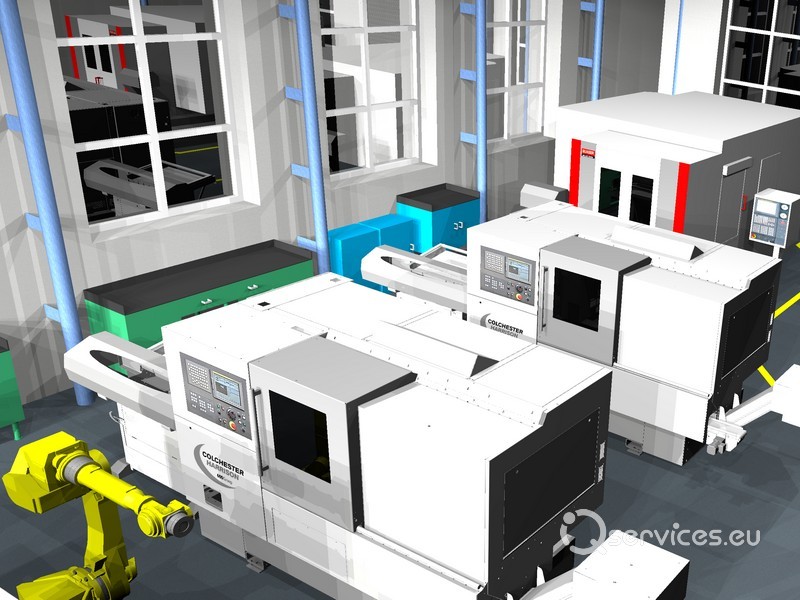

Laser scanning and 3D models of production halls and facilities are widely used in industrial engineering. In today’s “digital world”, all activities related to the running of companies are already carried out on computers. This is no different for process analyses where real 3D models are used. These represent the actual state transferred to the software interface and are used for activities such as:

- Optimisation of material flows

- Workplace optimisation

- Removing bottlenecks

- Minimisation of production space

- Production simulation

Benefits of 3D planning

3D planning in conjunction is one of the new techniques for designing manufacturing systems. With 3D planning, we have all the real constraints that actually exist, so we can design the new production without clashes and without additional changes during implementation.

Reduction of design time

visualisation and animation of future processes

zero-error scheduling (collision detection)

reducing the cost of additional changes when implementing changes

the location of new machines (equipment manufacturers provide 3D models of their equipment)